A Beginner’s Guide to Understanding the Functionality of Industrial Scales

A Beginner’s Guide to Understanding the Functionality of Industrial Scales

Blog Article

Just How Commercial Scales Job: An Extensive Introduction for New Users

Recognizing the auto mechanics behind commercial scales is important for new users that desire to make sure precision in their measurements. As we explore these elements, one need to think about just how these components engage to improve performance in varied industrial applications.

Essentials of Industrial Scales

Industrial scales are necessary devices made use of throughout different sectors, consisting of production, logistics, and agriculture, to make sure exact weight measurements of hefty lots. The basic principle behind commercial scales involves the conversion of weight right into a measurable kind that can be displayed digitally or analogically. These scales use different systems, such as lots cells or mechanical levers, to establish the weight of items put upon them.

Along with their measurement capabilities, industrial ranges are designed to withstand extreme atmospheres, featuring robust building that resists dust, moisture, and hefty influences. Calibration and maintenance are essential to ensure precision, as also minor discrepancies can lead to considerable monetary ramifications. By recognizing the essentials of commercial ranges, individuals can appreciate their value in various industrial applications.

Kinds Of Industrial Scales

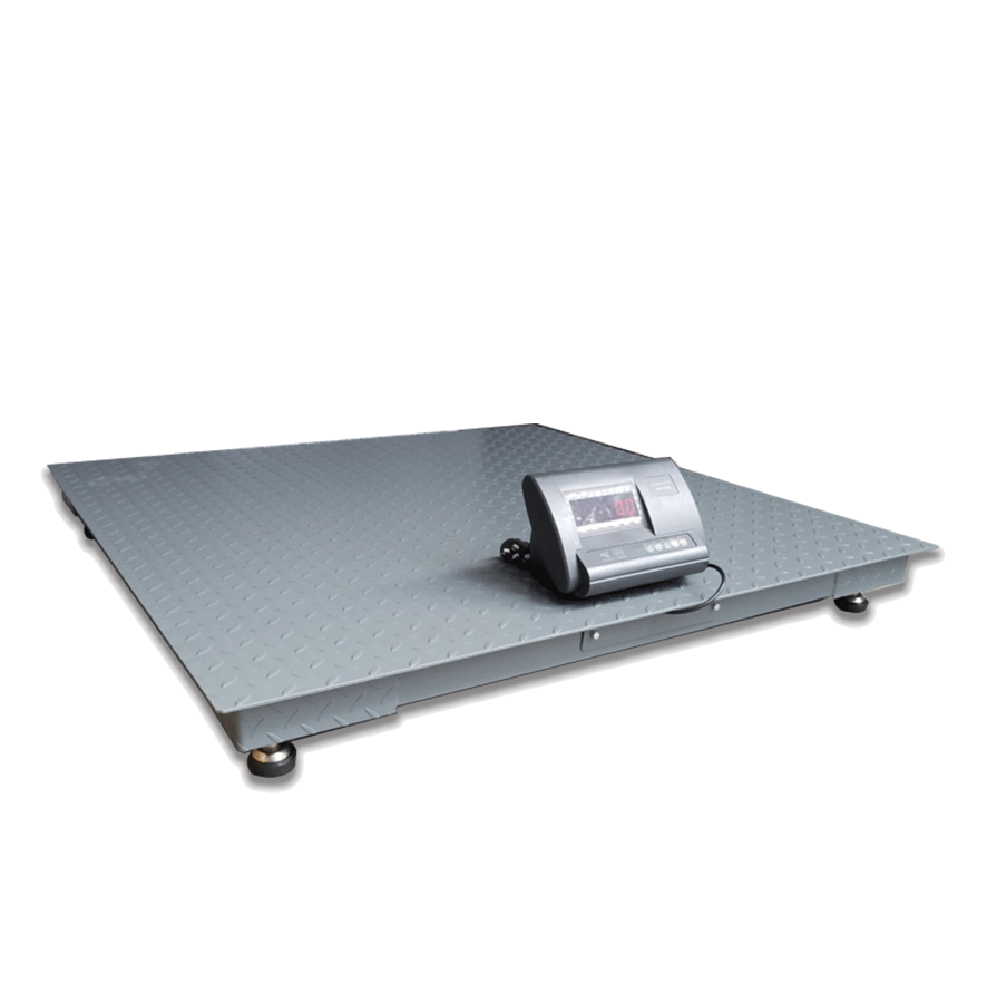

Various types of commercial ranges accommodate the varied demands of different sectors, each developed to deal with specific weighing jobs with accuracy and integrity. Amongst the most usual kinds are floor scales, which are suitable for evaluating hefty and large items. These scales usually include huge systems and can suit palletized items, making them essential in storage facilities and delivery centers.

One more kind is bench scales, which are commonly used for smaller sized items in manufacturing and retail settings. They give accurate measurements for items that call for accuracy, such as chemicals or parts in production line (Industrial Scales). For mobile operations, mobile scales offer adaptability and convenience of transportation, appropriate for fieldwork or short-term installments

In applications calling for high-capacity dimensions, such as wholesale material handling, crane scales and load cells are used. These ranges can determine lots suspended from a crane or various other training apparatus, making sure safety and precision during operations. In addition, specialized scales like checkweighers are used in assembly line to preserve top quality control by making certain that items meet weight specs. Each kind of industrial range plays a critical role in boosting operational efficiency and precision throughout different sectors.

Just How Considering Devices Work

Weighing devices are necessary elements that enable precise dimension of mass across different commercial scales. These devices utilize different concepts of physics and design to supply exact weight readings, important for stock management, quality control, and compliance with regulatory criteria.

One common kind of evaluating mechanism is the tons cell, which operates on the concept of pressure evaluates. When a lots is applied, the load cell warps somewhat, creating an electrical signal symmetrical to the weight. This signal is after that transformed into an understandable weight measurement by the range's electronics.

An additional widely utilized system is the mechanical equilibrium, which uses a system of bars and weights. Industrial Scales. This approach counts on the principle of equilibrium, where the weight of the object being determined is stabilized versus recognized weights, enabling for direct dimension

In addition, hydraulic and pneumatically-driven ranges utilize fluid characteristics concepts to determine weight. These systems use the pressure put in by a lots to determine weight, supplying high precision for large lots.

Appropriate Use Strategies

When utilizing commercial ranges, sticking to appropriate use strategies is crucial for guaranteeing accurate dimensions and maintaining equipment integrity. It is essential to pick the appropriate scale for your certain application, as scales differ in ability and precision.

Before weighing, make sure that the range is put on a secure, level surface area complimentary from disturbances or vibrations. This will certainly help to lessen errors triggered by exterior elements. In addition, calibrate the range according to the producer's specs prior browse around this web-site to make use of, ensuring that it is functioning correctly.

When positioning products on the scale, distribute the weight uniformly to stay clear of tipping or damaging the tools. Constantly permit the range to maintain before taping the weight, as changes may happen during preliminary placement. For bulk materials, utilize containers that are proper for the range dimension to avoid overloading.

In addition, stay clear of positioning extremely hot or cool items straight on the range, as temperature variants can affect accuracy. Keep the weighing platform tidy and complimentary of debris to prevent contamination and make sure reliable results. By adhering to these methods, users can maximize the efficiency and long life of their commercial scales.

Maintenance and Calibration Tips

Making sure the durability and accuracy of commercial scales calls for diligent upkeep and regular calibration. A preventive maintenance routine is crucial; it must consist of routine examinations to recognize wear and tear, particularly on lots cells and other sensitive components. Regularly cleansing the scale's surface area and ensuring the bordering location is without debris will assist maintain its honesty and performance.

Calibration is similarly necessary and need to be done at routine intervals or whenever the scale experiences considerable modifications in temperature, humidity, or physical displacement. Utilize qualified calibration weights that are traceable to nationwide requirements for precision. Record each calibration session diligently to track performance with time and recognize any type of patterns or recurring problems.

Train all operators on proper range usage and upkeep procedures to ensure constant performance and precision. By adhering to these upkeep and calibration ideas, users can boost the integrity of their industrial scales, making certain optimum operation in any kind of setting.

Conclusion

Recognizing the auto mechanics behind industrial scales is vital for brand-new users that want to guarantee accuracy in their measurements.Industrial ranges are crucial tools used throughout various fields, consisting of production, logistics, and agriculture, to ensure exact weight measurements of hefty loads. The basic principle behind industrial ranges involves the conversion of weight read review right into a quantifiable form that can be presented electronically or analogically. By comprehending the essentials of commercial scales, users can value their value in different industrial applications.

In verdict, understanding the operation and upkeep of industrial ranges is vital for guaranteeing exact weight dimensions in various applications. (Industrial Scales)

Report this page